GRAPHITE BLOCKS

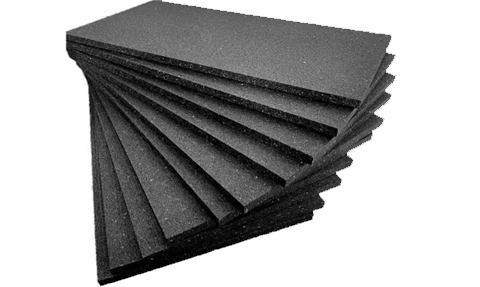

Graphite blocks, made from high-purity carbon, combine excellent thermal stability, electrical conductivity, and resistance to chemical corrosion and wear. They withstand extreme temperatures and harsh environments, making them essential in industries like metallurgy, electronics, and chemical processing. Available in types such as isostatic (for high precision), molded (cost-effective and machinable), vibrated (economical for medium-density uses), and extruded (general purpose), graphite blocks offer versatile solutions tailored to diverse industrial needs.

PRODUCT VARIANTS

ISOSTATIC GRAPHITE BLOCKS

We provide a wide range of high-density isostatic graphite, tailored for industries such as continuous casting dies for brass, copper, and aluminum, electric discharge machining (EDM), and vacuum evaporation of metals like aluminum, gold, and silver. Our graphite is also ideal for semiconductor applications, including crucibles, sealing rods, jigs, boats, as well as dies and molds. We offer customizable packaging options to meet your specific requirements.

| Parameters | GG-5 | GG-6 | GG-7 | GG-9 |

|---|---|---|---|---|

| Bulk Density (gm/cm³) – min | 1.85-1.90 | 1.91 | 1.85-1.90 | 1.85 |

| Specific Resistance (µΩ.m) | 8.5 | 8-9 | 11-13 | 11-13 |

| Shore Hardness | 48 | 53 | 65 | 70-75 |

| Porosity (%) | 13% | 11% | 12% | 12% |

| Flexural Strength (MPa) | 46 | 55 | 60 | 65 |

| Compressive Strength (MPa) | 85 | 100 | 115 | 125 |

| Maximum Grain Size (µm) | 13 | 8 | 7 | 5 |

| Ash (PPM) | 50 | 50 | 50 | 30 |

Molded Graphite Blocks

Our molded graphite blocks offer excellent machinability and durability, making them ideal for furnace linings, casting molds, crucibles, and pressure sintering in diamond tool manufacturing. They resist high temperatures, corrosion, and thermal shock while maintaining dimensional stability. With good electrical and thermal conductivity, molded graphite blocks are versatile for various industrial uses. Custom packaging is available to meet your needs.

| Parameters | GG-4 | GG-4B | GG-4L | GG-4H |

|---|---|---|---|---|

| Bulk Density (gm/cm³) – min | 1.78 | 1.76 | 1.80 | 1.80 |

| Specific Resistance (µΩ.m) | 8-11 | 13-15 | 8-11 | 11-13 |

| Shore Hardness | 42 | 64 | 45 | 65 |

| Porosity (%) | 17 | 13 | 16 | 16 |

| Flexural Strength (MPa) | 38 | 45 | 40 | 48 |

| Compressive Strength (MPa) | 65 | 95 | 70 | 110 |

| Maximum Grain Size (µm) | 13-15 | 13-15 | 13-15 | 13-15 |

| Ash (PPM) | 50 | 100 | 500 | 500 |

| Thermal Conductivity (W/m-k) | 115 | 125 | 125 | 130 |

| Thermal Expansivity (10⁻⁶/°C) | 5.46 | 5.65 | 4.90 | 5.70 |

Vibrated Graphite Blocks

Our vibrated graphite blocks are valued for their good strength and thermal conductivity, making them suitable for applications like glass manufacturing, foundry equipment, riser tubes, and stopper heads. They offer reliable resistance to abrasion and corrosion, with excellent machinability for custom shapes and sizes. Custom packaging options are available to ensure safe delivery.

| Specification | Bulk Density ≥ (g/cm³) | Compressive Strength ≥ (MPa) | Bending Strength ≥ (MPa) | Specific Electrical Resistance ≤ (µΩ.m) | Maximum Particle Size (mm) |

|---|---|---|---|---|---|

| 500×400×1950 | 1.76 | 40 | 21 | ||

| 400×400×2100 | 1.76 | 40 | 21 | ||

| 510×510×1800 | 1.76 | 40 | 21 | ||

| 650×450–500×1800 | 1.76 | 40 | 21 | ||

| 870×415×1800 | 1.74 | 38 | 20 | 8 | |

| 940×508×2800 | 1.74 | 38 | 20 | 8 | |

| Φ660×600 | 1.74 | 38 | 20 | 8 | 0.8 |

| Φ730×360 | 1.72 | 36 | 18 | 9 | 2 |

| Φ830×360 | 1.72 | 36 | 18 | 9 | 2 |

| Φ830–930×370–420 | 1.72 | 36 | 18 | 9 | 2 |

| Φ1430×360 | 1.72 | 34 | 17 | 9 | 2 |

Know More About The Product

Applications

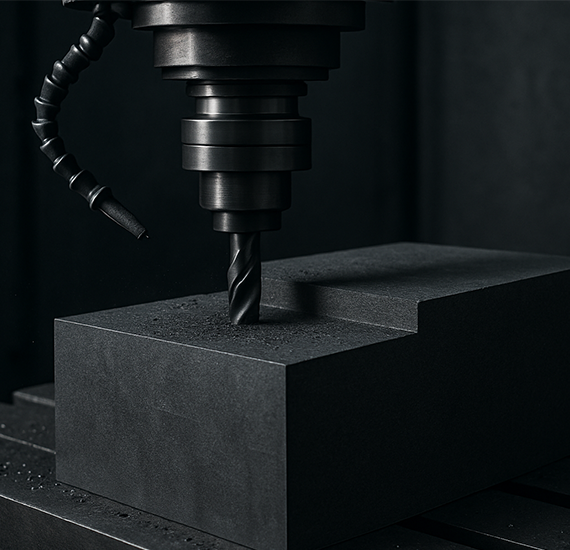

EDM Electrodes

Furnace Linings

Die & Mold Manufacturing

Heating Elements

Graphite Crucibles

Thermal Insulation Panels

Casting and Foundry Equipment

Chemical & Petrochemical Plants

Innovation and Excellence

Advantages at Goel Carbon

Energy Efficient Carbon Solutions:

We help industries reduce energy losses by supplying high-performance carbon and graphite components. Goel Carbon Products Pvt Ltd specializes in engineered carbon blocks, carbon vanes, and advanced grades like electrographite, designed to enhance conductivity, thermal efficiency, and durability—contributing to overall energy savings in power tools, furnaces, and process industries.

Precision Customization:

Need custom dimensions, densities, or grades for your carbon or graphite application? At Goel Carbon, our in-house engineering and R&D capabilities enable us to deliver tailor-made carbon brushes, blocks, rods, and mechanical parts for your exact needs—whether it’s for OEMs, electric motors, or specialized industrial uses.

End-to-End Technical Support:

We provide complete support—from selecting the right grade to optimizing performance for specific applications. Our technical team assists with material selection, performance troubleshooting, and custom product development to ensure the best-fit carbon solution for your industry—from power tools to chemical plants.

For further inquiries

info@goelcarbon.com

Have questions? We’re here to help! Whether you need technical support, pricing, or detailed product information, our team is ready to assist with any inquiries you may have regarding carbon blocks, carbon brushes, graphite products, or specialty components.