GRAPHITE EDM ELECTRODES

High-Performance Electrodes for Precision Electrical Discharge Machining

Premium-grade Graphite EDM Electrodes engineered for precision, speed, and durability. Manufactured from isostatic and ultra-fine grain graphite, these electrodes ensure uniform spark erosion, minimal tool wear, and outstanding dimensional accuracy — ideal for both roughing and finishing in high-precision EDM applications.

PRODUCT VARIANTS

Roughing Electrodes

Designed for fast material removal during the initial stages of EDM machining. These electrodes are typically made from medium-grain graphite, offering a balance of strength and conductivity. The goal is to quickly erode bulk material, forming the general shape of the cavity. Surface finish and dimensional precision are secondary at this stage.

Key Benefits:

- High erosion rate

- Lower cost per electrode

- Good wear resistance

- Ideal for bulk cutting and deep cavities

- Typical Use:

- Tool and die pre-shaping

- Large cavities in molds

- Situations where speed is more important than surface finish

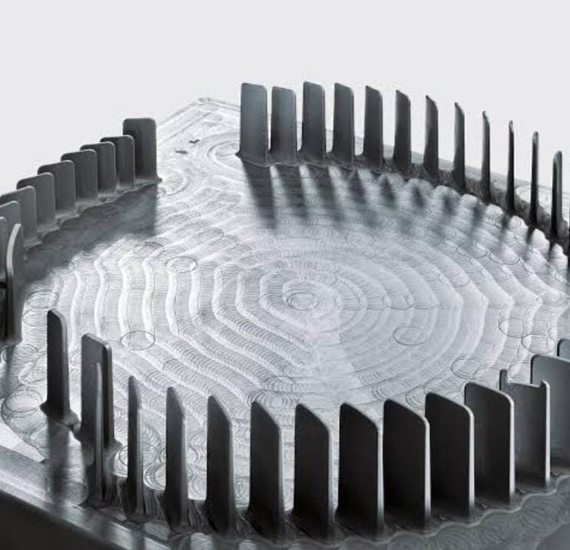

Finishing Electrodes

Used in the final stage of EDM machining to refine geometry and surface quality. Made from ultra-fine grain isostatic graphite, these electrodes provide excellent dimensional accuracy and superior surface finishes. They are essential where precision, detail, and aesthetic surface quality are critical.

Key Benefits:

- High-precision machining

- Excellent surface finish (Ra as low as 0.2–0.4 μm)

- Minimal electrode wear

- Suitable for fine features and tight tolerances

- Typical Use:

- Final machining of molds and dies

- Medical, aerospace, and electronics components

- Complex cavities and detailed profiles

Hybrid Electrodes (Roughing + Finishing)

These electrodes are engineered to handle both roughing and finishing in a single tool, reducing the need for multiple electrode changes. Typically made from high-density, fine-grain graphite, they offer a compromise between erosion rate and surface finish. This variant is useful for shops that prioritize efficiency and cost savings.

Key Benefits:

- Reduced electrode changeover

- Balanced speed and accuracy

- Improved process efficiency

- Moderate surface finish and wear rate

- Typical Use:

- Short-run production jobs

- Medium-complexity molds and dies

- Situations where cycle time and productivity are critical

Know More About The Product

Applications

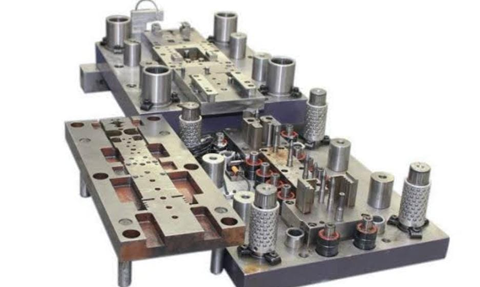

Tool & Die Manufacturing

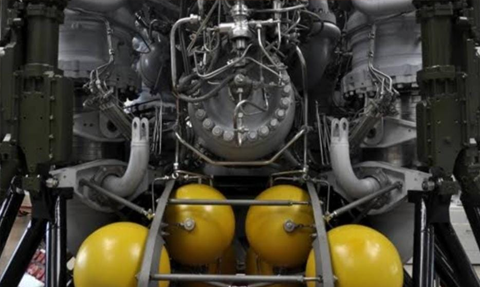

Automotive Industry

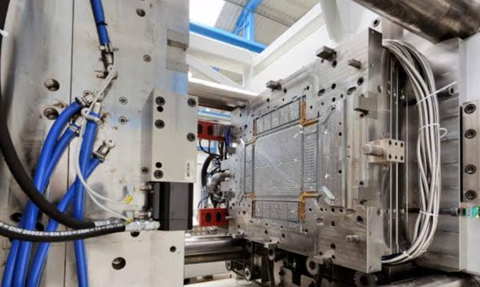

Plastic Injection Molding

General Precision Engineering

Innovation and Excellence

Advantages at Goel Carbon

Energy Efficient Carbon Solutions:

We help industries reduce energy losses by supplying high-performance carbon and graphite components. Goel Carbon Products Pvt Ltd specializes in engineered carbon blocks, carbon vanes, and advanced grades like electrographite, designed to enhance conductivity, thermal efficiency, and durability—contributing to overall energy savings in power tools, furnaces, and process industries.

Precision Customization:

Need custom dimensions, densities, or grades for your carbon or graphite application? At Goel Carbon, our in-house engineering and R&D capabilities enable us to deliver tailor-made carbon brushes, blocks, rods, and mechanical parts for your exact needs—whether it’s for OEMs, electric motors, or specialized industrial uses.

End-to-End Technical Support:

We provide complete support—from selecting the right grade to optimizing performance for specific applications. Our technical team assists with material selection, performance troubleshooting, and custom product development to ensure the best-fit carbon solution for your industry—from power tools to chemical plants.

For further inquiries

info@goelcarbon.com

Have questions? We’re here to help! Whether you need technical support, pricing, or detailed product information, our team is ready to assist with any inquiries you may have regarding carbon blocks, carbon brushes, graphite products, or specialty components.